Why use recycled parts and what should you ask for

Why Use Recycled Parts

The professional automotive recycling industry has long been an advocate for consumer choice and a competitive automotive parts market. Each day over 500,000 recycled OEM parts are sold directly to vehicle owners, repair shops and automobile dealers. Using recycled OEM parts for your vehicle repair is perhaps the purest form of recycling. Recycled parts will significantly reduce your vehicle repair costs without sacrificing quality. Choose Recycled Parts!

Value

The genuine recycled, original equipment manufactured (OEM) automotive parts sold by IADA member facilities play a critical economic role in the market, providing consumers with a choice for their vehicle repair needs. Without the existence of recycled OEM parts, many times there would be no alternative part options to an expensive “new” part.

Most insurance policies allow for the utilization of recycled parts in vehicle repairs, and know that recycled OEM parts offer quality, safe parts at a fraction of the cost of new OEM parts. Due to the complexity of the today’s motor vehicle, for a consumer driving a 7 year old vehicle that is involved in an accident, that vehicle will be declared a Total Loss 75 percent of the time. Utilizing recycled OEM parts helps extend the lives of many vehicles that would be prematurely taken off the road.

In addition to insurance and collision repair industry recognition of the value of OEM recycled parts, state court actions also have ruled on this issue. In 2015, the West Virginia Supreme Court of Appeals affirmed the use of salvage/recycled OEM crash parts in vehicle repairs, found that recycled parts are diametrically different from aftermarket parts and applauded automotive insurers for using measures to reduce premium costs for their customers.

Quality

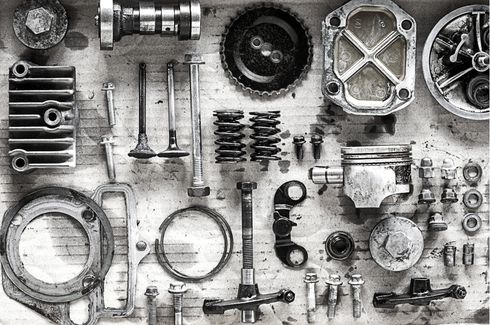

Professional automotive recycling operations have robust product assurance and quality control procedures in place to identify parts that do not meet industry accepted standards. These operational safeguards distinguish the parts sold by IADA member businesses from those sold by what are commonly referred to as “junkyards.”

Parts sold by professional automotive recycling facilities are recycled, genuine, original OEM parts that meet OEM requirements. They are OEM parts, designed by the OEM, and built to meet the OEM requirements for fit, finish, durability, reliability and safety.

The automotive recycling industry has become increasingly sophisticated in methods of processing, inspecting, evaluating and analyzing OEM parts harvested from salvage vehicles. At a typical professional automotive recycling facility, these processes may include a review of the vehicle’s build codes, capturing images of the vehicle and its component parts to track the vehicle part record, verification of interior colors, conditions and option lines (seats, dash board, door parts), assessing the extent and type of any damage, and checking the vehicle identification number. A inspection of parts or assemblies may take place after the disassembly process has taken place. These practices described are industry practices of well-run professional automotive recycling businesses.

Environmental

Using recycled OEM auto parts for your vehicle repair is the ultimate environmental choice. Automobiles are among the most recycled commodities in today’s marketplace and the reutilization of quality OEM parts provide preserves natural resources, reduces the demand for scarce landfill space, and plays an important role in reducing air and water pollution.

Approximately 86 percent of a vehicle’s material content is recycled, reused or used for energy recovery. Using recycled scrap iron and steel reduces the use of new iron ore. Every ton of new steel made from scrap steel conserves:

- 2,500 lbs. of iron ore

- 1,400 lbs. of coal

- 120 lbs. of limestone

In addition to conserving natural resources, automotive recycling plays an important role in reducing air and water pollution, and solid waste generation. Each year the industry collects and reuses or recycles an estimated:

- 8 million gallons of gasoline and diesel fuel

- 24 million gallons of motor oil

- 8 million gallons of engine coolant

- 5 million gallons of windshield washer fluid

- 96% of all lead acid batteries

Additional energy and resource conservation is realized by recycling rebuildable “core” parts to the automotive parts rebuilding industry.